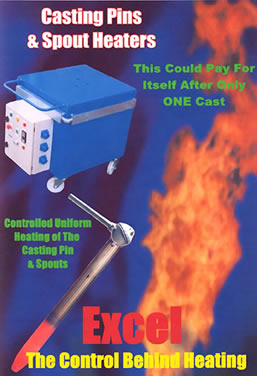

Casting Pins - Pin Heaters - Spout Heaters

These electrically heated Pin Heaters, and Spout Heaters have been specially designed for the Direct Chill (D.C.) casting process. The conventional way of pre heating with an open flame gas heater is not only dangerous from a point of that the flame may be inadvertently blown out without in many cases any automatic gas shut off system, but also from the very often uncontrolled flame.

These electrically heated Pin Heaters, and Spout Heaters have been specially designed for the Direct Chill (D.C.) casting process. The conventional way of pre heating with an open flame gas heater is not only dangerous from a point of that the flame may be inadvertently blown out without in many cases any automatic gas shut off system, but also from the very often uncontrolled flame.

There are a number of distinct advantages of the Excel Heat Electric Pin Heaters and Spout Heaters, they are uniquely designed to heat the pins and spouts only where the heat is required greatly increasing the efficiency, and effectiveness over gas.

Because the electrical heat is uniformly spread around the required area there is little or no variation of heat radiating onto the ceramic pins and spouts, which eliminates the hot and cold spots often seen when using gas. Add to that the fact that due to the concentration of heat it is unlikely that it will cause damage to the surrounding equipment, for instance the filter bags or automatic control equipment.

The pin heaters and spout heaters come as a complete unit requiring only to be connected to a suitable power supply for it to be ready for use. The unit comes with 5 meters of flexible wire reinforced cable as standard.

Once electrically connected, the casting pins are then placed vertically through the top of the heating compartment and the individual spout heaters come with 3,000mm flexible lead allowing you to place them into the casting spouts and then simply press the start button for the pre heating process to begin.

The spout heaters are designed on a low 110 voltage, which is internally derived from the mains incoming supply. All the control equipment is mounted in a lockable panel and mounted on the Pin heater casing.

The unit is mounted on swivel casters for mobility to remove from the immediate casting area before casting begins allowing a clearer access to the casting machine at the start of cast.